RadLaunch 2025

Connecting and Promoting Innovative Applications and Tech Start-Ups

“RadLaunch serves as critical support to companies working in the UV/EB space as they take their first steps on the long and challenging road to commercialization. Many companies that have an excellent idea and perhaps early positive lab results are missing the contacts and network that will take them past the concept phase. one of the most valuable things that RadLaunch offers is an introduction to member companies such as material and equipment suppliers and end users that can furnish support and guidance.”

Mike Idacavage, Co-Chair, RadLaunch

A Unique Idea Accelerator for UV+EB Start-ups, Students & Innovators

RadTech, the nonprofit trade association for UV+EB technologies (ultraviolet and electron beam), invites your innovation, start-up ideas, concepts and prototypes.

New materials, optics, design, printing, packaging, 3D printing, inkjet, building products, plastics, medical, electronics. (and more!)

Learn more about our new RadLaunch competition….

2025 UV+EB DEGRADABILITY CHALLENGE

The RadTech Degradable Materials Task Force is pleased to announce the 2025 UV+EB Degradability Challenge. This challenge highlights an important pillar of sustainability: designing products with their end-of-life (EOL) in mind. When an item is discarded, it all too often ends up contributing to the accumulation of non-degradable waste in landfills and ecosystems. Even most “recyclable” plastics meet a similar fate, with only an estimated 9% of the world’s plastic waste being recycled. Innovation and investment in degradable materials can help combat the growing pollution crisis.

The 2025 UV+EB Degradability Challenge aims to promote research and development of degradable materials that utilize UV+EB technology. We invite submissions detailing current or recent projects as well as research proposals based on previous work and/or literature. We welcome materials across the product development spectrum that have demonstrated evidence of degradability or strong theoretical argument supporting degradability. See below for examples of materials and degradation standards.

K-12 Rising Scientists are encouraged to apply for special recognition of their work with UV or EB.

RadLaunch Class of 2024

UV Cured Bio-Based CO2 Sequester Adhesive

UV Cured Bio-Based CO2 Sequester Adhesive

Nvirovate Materials, Inc

Nvirovate Materials have developed a portfolio of bio-based, compostable soybean oil adhesives that are UV cured. Utilizing technology based on a patent portfolio licensed from Oregon State University, Nvirovate have formulated and produce the only bio-based pressure sensitive adhesives in the world that are CO2 negative, compostable and as a result of UV cure only require 15% of the energy to process as compared to legacy fossil fuel-based adhesives.

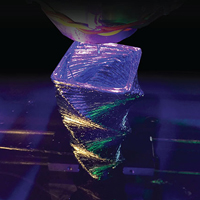

Volumetric 3D Printing, Subzero Molding/Casting and Agile methodologies, potentially reshaping the landscape of 3D solar and battery cell manufacturing

Volumetric 3D Printing, Subzero Molding/Casting and Agile methodologies, potentially reshaping the landscape of 3D solar and battery cell manufacturing

Topshelf Enterprises DBA T3DP

These cutting-edge technologies enable the efficient creation of intricate micro and macro parts from glass, metal, and ceramics at subzero and room temperatures, significantly enhancing production precision. By adopting agile methodologies, manufacturers can swiftly adapt to evolving market demands and technological advancements. This integration significantly boosts scalability and adaptability, promising transformative impacts on the manufacturing processes in the solar, battery, micro-optics, and generativity designed auto parts.

Photoresponsive Coatings with Targeted Antibacterial Behavior

Photoresponsive Coatings with Targeted Antibacterial Behavior

Azodent, Inc.

Scientists at the University of Colorado, have designed a polymer coating that can be used to prevent biofilm accumulation and infections on implants, prostheses, catheters, and endoscopes. This technology is being commercialized by Azodent Inc., with a wide range of potential applications in the industrial coatings market, including for non-stick coatings, touch screens, and de-ice coatings for aircraft. Additionally, the photoresponsive material can also selectively inhibit dental cavities-causing bacteria, and regenerate dental pulp to initiate the formation of dentinal ridges. Such genus-specific inhibition and regenerative properties within the same material are rare in dentistry, therefore the dental market is likely the initial market for this technology.

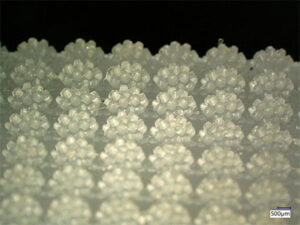

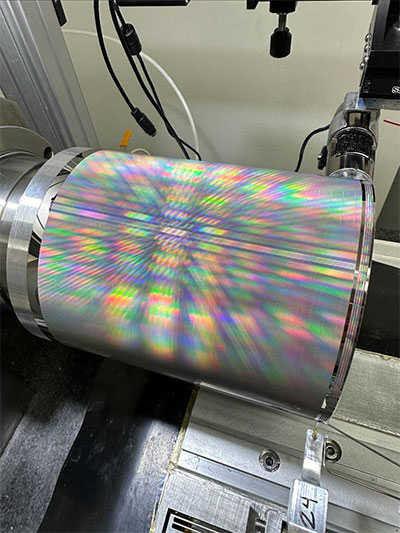

Seamless Nanopatterned Coatings to Enable Large-area Metamaterials with UV Technology

Seamless Nanopatterned Coatings to Enable Large-area Metamaterials with UV Technology

Smart Material Solutions (SMS)

SMS is a precision engineering company developing scalable nanofabrication methods, tooling, and materials for large-area nanopatterning. Its dedicated team of materials scientists and mechanical engineers integrates seamless cylindrical molds with roll-to-roll manufacturing to add new functionalities to surfaces. SMS’s technology includes forming a UV-cured layer with trillions of micro and nano structures per square meter, which may serve as an outer coating or resist. By tailoring these structures, SMS can cater to a diverse range of metamaterial interests, including solar energy, biosensors, virtual reality, self-cleaning surfaces, and more.

3D-printed Anatomical Models with Thiol-ene UV Curable Coatings

3D-printed Anatomical Models with Thiol-ene UV Curable Coatings

Maedditiva, Tecnologico de Monterrey

Identifying a need for 3D-printed soft transparent patient-specific anatomical models with high fidelity, suitable for cardiovascular applications like pre-procedural planning, training, and flow visualization, the group developed a simple method that involves the use of thiol-ene coating as post-processing step to flexible SLA 3D-printed parts–increasing the transparency of the final product, while adjusting the mechanical properties close to those of human aortic tissue and retaining a high anatomical fidelity. Thus far the group’s “phantoms” have been utilized in 13 complex surgeries and by medical companies to test new stent graft designs.

LUMII, EXPERIENCE 3D

POLY6 TECHNOLOGIES TURNS CITRUS RINDS INTO BIO-BASED MATERIALS

LIGHT ACTIVATED MEDICAL DEVICES

RadLaunch Chairs

Paul Share

Mike Idacavage

Radical Curing LLC

RadTech International NA

6935 Wisconsin Ave, Suite 207

Chevy Chase, MD 20815

(240) 497-1242

uveb@radtech.org